Driving railway vehicles

Driving railway vehicles

- Driving rail vehicles biaxial - line 211

- Driving rail vehicles triaxial - A 314

- Driving rail vehicles quadriaxial - A 415

Special driving railway vehicles for light shunting and manipulation with railway wagons designed to ensure technological production operator onsite loading and unloading takes place. Cable shunting devices

Cable shunting devices is designed for the rail cars shunting during their loading and unloading at the sidings, filling stations of liquid products and terminals. The device is able, according to the local conditions, to put in move and to brake the rail cars set with the total weight of up to 2500 t, device PZ 15 of up to 500 tons in both directions.

Cable shunting devices

Cable shunting devices is designed for the rail cars shunting during their loading and unloading at the sidings, filling stations of liquid products and terminals. The device is able, according to the local conditions, to put in move and to brake the rail cars set with the total weight of up to 2500 t, device PZ 15 of up to 500 tons in both directions. Special equipment

Special equipment

- Dynamic manipulator HW1E

- Electromechanical Train Wheel Stopper EMVZ-02

- Rail locking mechanism KAM-60-8

The dynamic manipulator HW1E has been developed for the wagons rotary tipplers with aim to catch and stop incoming loaded wagons, their appropriate arrangement, and once they are unloaded, their pull out. An important condition is the observance of the velocity of incoming wagons, which can be guaranteed.

Electromechanical Train Wheel Stopper EMVZ-02 has been developed for places on marshalling yards and railway sidings, where the track operator regularly secures the wagons with a wheel stopper.

Rail locking mechanism KAM-60-8 is intended for locking and holding stationary railway wagons on inclined lines during operation with individual wagons.

Cable shunting device PZ 15, PZ 15 DUO

The cable shunting device PZ 15 is intended for rail cars shunting during their loading and unloading at the railway sidings, filling stations of the liquid products and terminals. It is capable according to the local conditions to set in motion and to brake the fleet of wagons of total weight of up to 500 tons in both directions.

Basic description

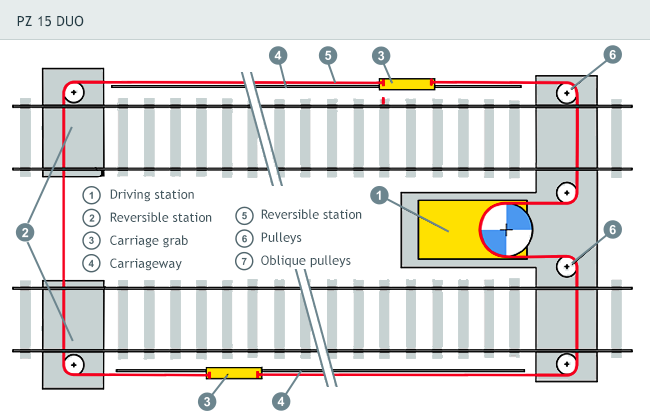

We offer 2 versions of PZ 15: basic → for 1 rail and PZ 15 DUO → shunting of rail cars takes place always on one of the two parallel tracks. The presence of an operator in the vicinity of rail cars is necessary only to turn on or detach towing arm of crab.

The device PZ 15 consists of basic units - driving station, reversible station and crab with arm and drawn on travel groove outside the trackage with the help of the pull rope. It is possible to couple the crab’s hauling arm and the lateral hook of the wagon in the set. The part of supply includes electric switchboard with control system and the rope’s tightening device.

Control

The traction and braking of the set of wagons are controlled by frequency converter. The programming automatics in the technology distributor allows for logical links to existing technology equipment such as installed at the siding (filling nozzles and arms, rail scale, etc.).

The whole shunting device technology can be designed for and implemented in the environment marked with the danger of explosion.

Course of shunting using pz 15

- The shunting locomotive pushes the set of wagons to the shunting device location.

- The operator uncouples the set of wagons from the locomotive, which can travel away in order to perform another tasks.

- The operator, with help of radio remote control, will shift the traveling crab under lateral hook of one of wagons intended to be shunted. The operator will grab towing arm at holder, lifts it up and, at the same time, by virtue of micro-motion of the crab moves precisely to the hook, executes coupling and secures the pin on the hook.

- It moves a single wagon or more rail cars to a designated place.

- After the wagons are loaded, the operator moves them in the same manner to the place, where they can get coupled with shunting locomotive.

Driving station

Is consists of welded travel frame, which through the use of anchor bolts is anchored to a concrete base where the main drive travels. The drive frame contains driving unit composed of three-phase airt-cooled electric motor and epicyclical gear with driving rope disk.

Placed on a concrete base of driving station are pulleys, guiding driven rope to the reversible station, as well as to towing crab. The tightening of the transport rope takes effect in a standard manner with the help of hydraulic unit.

Reversible station

Consisting of two welded frames with deposited pulleys on an iron-concrete basement outside the trackage.

The pulleys are ensuring guidance of transport rope from reversible station to traveling crabs as well as to driving station. Then structure is protected by the metallic plate cover.

Carriageway, crab and pull rope

Guiding grooves consist of the steel I – profile at a distance of about 1400 mm from the track centre (according to the specification of wagons), in which profile there is the traveling crab running. It has range of ± 100 mm from the axis of guiding groove for fixing wagon’s lateral hook and it is protected against running off the grooves at the end positions by double end-point sensors. The crab itself consists of welded steel structure with towing arm equipped with booster spring for easy pin handling in terms of switch on and detach.

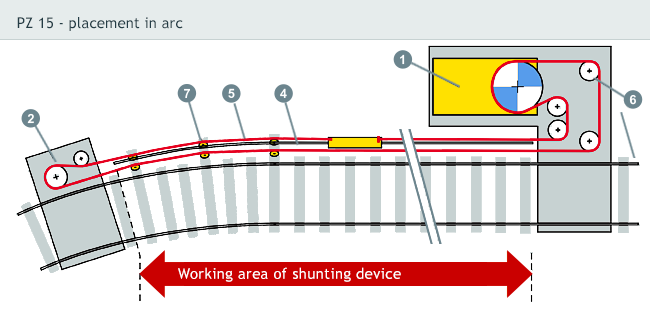

The PZ 15 device can operate in arcs and points. It is possible to hide the taxiway in a loading ramp pavement or a road crossing. The rope is fixed to the crab by dead eye and clamps.

An unlubricated steel pull rope is designed according to the technical standard STN EN 12385-4 with diameter pursuant to designed load. The movable part of the rope in the trackage is supported by the rollers that reduce the rope’s abrasive wear and keep it clean.

Control

As standard, the shunting device is controlled with the help of mobile radio set, which is necessary during the pin to hook coupling. ↓

The operator then can handle the rail cars from any place on the track.

Another possibility is to control device from the local box placed at the clear spot beside the track. The service control point is the distribution box itself, which serves only for the needs of maintenance and repairs.

Download Type list »

-->

Fill in the questionnaire for particular specification of the equipment »

Cable devices

| Questionnaire | Type List | Photo Gallery |

| Basic technical data LTV-NV | |

|---|---|

| Tractive power* | 12 - 46 kN |

| Electric motor output | 5.5, 7.5, 11 kW |

| Max. velocity of trolley* | 0,4 m/s - load less 0,2 m/s - loaded |

| Max. weight of shunted set* | to 500 t |

| Permissible slope of trackage | max. 3 ‰ |

| Trackage | Shunting possible in arc and at adjusted crossing |

| Control |

|

| *According to local conditions and user’s requirements | |